Medical

Laird is a global leader in enabling and protecting sophisticated medical device designs.

Our deep talent pool and extensive experience allow us to help manufacturers find the right answers in design and mass component production – from conductive fabric heating patches to precision metals for glucose monitors.

Ensuring medical device protection and performance can be daunting. Laird resolves the most challenging, complex performance issues imaginable on the road to market. Our insight helps us spot and correct unnoticed design obstacles. We create improved medical device protection solutions and conduct vital simulations. Then we manufacture precision products for medical devices featuring extremely tight tolerances.

Laird’s insight is especially helpful whenever barriers arise unexpectedly. Any performance obstacle can threaten compliance. Those barriers can be staggering. Stray electromagnetic interference and unwanted heat can delay an entire launch. We tap our talent globally to help conquer the medical device industry’s unique hurdles. Just two are the regulatory framework and the critical nature of each component.

A holistic approach to medical device protection

Design flaws are unacceptable in medical devices. A life could hang in the balance.

Laird helps you properly manage risk.

We’ll encourage you to adopt a holistic, system-based approach to design.

By assessing various device components within the context of the larger system early in the design process – before the board is fully laid out – design engineers can optimize the limited real estate within a device.

This approach will allow design engineers to address EMI, thermal and structural challenges in a way that ensures long-term product reliability and performance.

We will help you unify your design process

For example, electrical engineers may work to mitigate EMI separately from the mechanical teams that tackle thermal issues. Since EMI and heat are interrelated, these efforts can clash.

A heat sink can help lower thermal loads, yet it can exacerbate EMI. Laird shows you how to address these challenges as one.

You can lower assembly requirements, reduce total cost of ownership and better identify flaws early on.

Laird encourages using simulation tools

Electromagnetic modeling, computational fluid dynamics and mechanical simulations.

These tools help determine the optimal architecture before committing to prototypes and tooling. Teams still have time to make large-scale changes.

By accounting for all elements in a device – from springs to EMI-reducing absorbers to thermal interface materials – holistically and early, design engineers can accommodate fast-moving medical technology innovations and improve their products.

Medical Capabilities

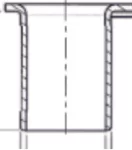

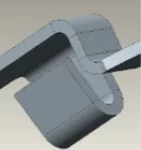

Insulin Pump / Continuous Glucose Monitoring Device

- Pivoting feature created from single strip of material

- Material is stamped in distinct steps into two components which are then joined in-die

- Deep drawn features with extremely high precision

- Feature is 9mm in height which is held +/- 0.09mm

- Diameter is -3.0mm

- Diameter of 3mm which is held +/- 0.025mm

- Linear areas generated by direct stamping operations (~10mm) held to +/- 0.04mm

- Linear areas generated by direct stamping operations (~10mm) held to +/- 0.04mm

- Management of complex bend angles with high repeatability and critical surface finishes in areas with multiple hit

Heating Patch for Pain Relief / Laird Selectively Plated Conductive Fabric

Goal

Improve the design of a layered, stack-up heating element to be used in a battery-driven conductive fabric product placed directly on the skin for pain relief.

Existing Design

Each half of heating patch had three separate heating circuits. Each copper-nickel wire circuit designed for 2-2.5W and 10-15 Ohm/meter. Traces length is 40-50cm

Analysis of Design Issues

- Original design for stack-up to be connected to the PCB featured a polyurethane (PU) bio layer, a polyester spunbond (PES) nonwoven conductive fabric layer, the heating element’s copper-nickel wire (11x0,05mm) and another PU bio layer with skin contact.

- Original design developed performance and assembly issues

- Batteries tended to overheat

- Extensive soldering required on assembly floor to create wire-based patch

- Use of wire added weight; wiring seen beneath bio layer created cosmetic concerns for users

Laird Recommendation

- Laird R&D had produced selectiveplating a nd high electrical conductivity onto both sides of standard or stretchable fabrics

- Use Laird Tex Heat selectively plated conductive fabric as active heating structure versus wires

Customer Application and Benefit

- Against the skin, the heating element’s stack-up included air-breathable PU film as the biocompatible layer

- Tex Heat selectively plated conductive fabric became the active heater structure versus wires

- Polyethylene terephthalate (PET) nonwoven fabric at 0.5-2mm became the insulation layer

- PU film became the cosmetic or outer layer

- The heating element was consolidated using Laird LT591 pressure sensitive tape