Thermoplastic Absorber

Structural Absorbers

Flexible solutions

Whenever 2D precut materials will not fit your unique design, our thermoplastic injection molded platform can give you the attenuation you need. Absorber materials are injected in a variety of complex 3D shapes. Magnetically or dielectrically loaded, our multiple grades can address cavity resonance and free space problems across the frequency band. Certain compounds loaded with specific fillers may be used in high volume applications that require reduction of interference and enhanced performance using absorber material. Because of their low out-gassing properties, these materials may be suitable for space applications.

We have injection molding capabilities in each region and will deliver final parts ready to use.

Benefits of our Injection Molded Absorbers

- Available in multiple resin systems

- Reflow compliant grades

- Fully customizable solutions are possible

- Low- to high-volume compliant process

Find or Design Your Absorber

Using Laird™ manufactured parts, our team of global experts and engineers create a custom design experience that is unrivaled by our competitors. Explore our robust line of absorber products or contact an engineer through customer service to discuss your next solution.

Thermoplastic Absorber Series

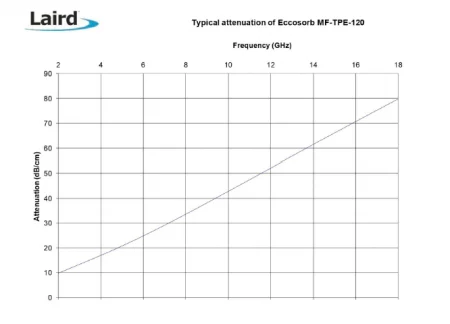

Eccosorb MF-TPE is the right choice within the thermoplastic absorber series when softness and elastomer flexibility is required for tolerances,

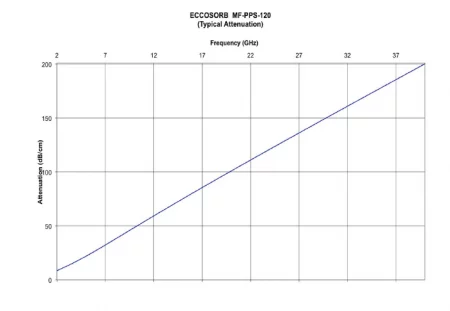

Polyphenylene Sulfide thermoplastic absorber Eccosorb MF PPS exhibit high temperature resistance up to 210 °c as well as compliancy to

Eccosorb MF-PP is a multi purpose grade covering general application as well as specific ones in automotive industry for example

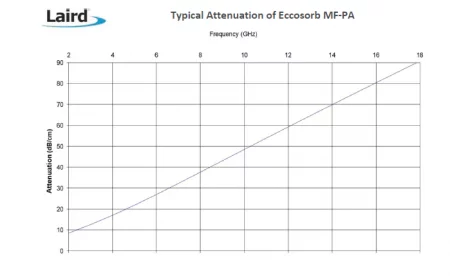

Eccosorb MF-PA represents a family of injection molded absorbers based on a thermoplastic matrix with high magnetic loss. Eccosorb MF-PA-120

EccosorbTM MF-LCP-115 is a magnetic loaded injection moldable absorber grade based on Liquid Crystal Polymer (LCP). Benefit from LCP resin

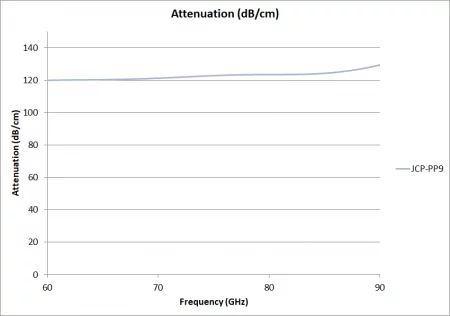

Eccosorb JCP-PP9 is an injection molded absorber grade based on a proprietary blended polypropylene based material made to match a

Reinforced with glass fiber, this absorber grade is exhibiting good stability and enhanced mechanical properties. This compound is loaded with

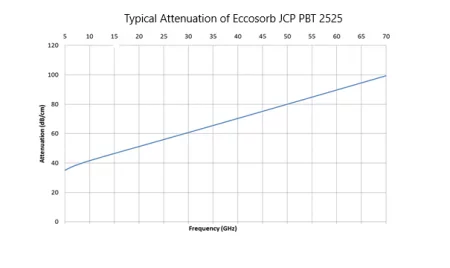

The thermoplastic contains polyamide with a proprietary filler for applications requiring enhanced performance for resonance and reflectivity in the higher