Gap Fillers

Thermal Interface Materials

What are Gap Fillers?

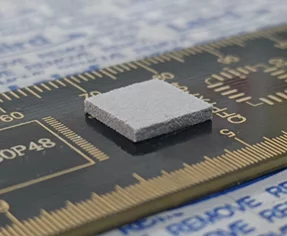

Thermal gap fillers are valuable aids as electronic component heat dissipation materials because of their thermal conductivity properties. They fill spaces and replace the air from them. Air is a poor conductor of heat. Aided by their thermal conductivity properties, gap fillers are scientifically engineered to increase overall heat transfer inside a device or system. They keep components cooler and within allowable thermal ranges.

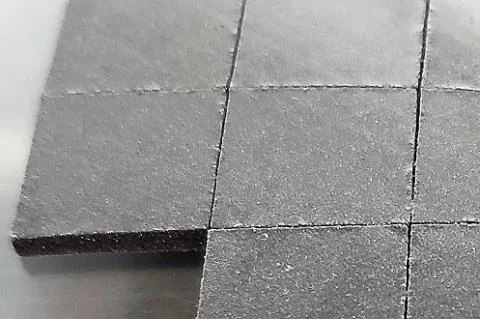

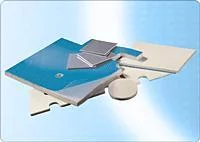

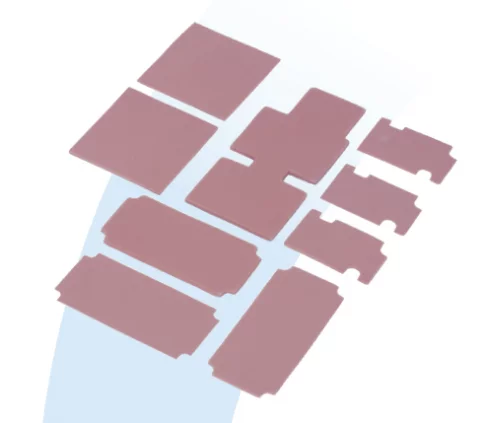

A gap filler is a class of thermal interface materials that fills “a large gap” between heat generating and heat dissipating surfaces. Often, one gap filler can cover multiple heat sources within an application. The material can be placed across three different heat sources with varying heights. A gap filler material is expected to be compliant without generating too much pressure within the system. Gap fillers are usually silicone based because silicone has many attractive properties such as surface wetting, high thermal stability, and physical inertness. Newer offerings can contain no silicone. The silicone is normally used as the binder within a gap filler system. The silicone matrix is then filled with thermally conductive fillers – BN, ZnO, and alumina. These fillers make up the functional portion of the gap filler which gives it its thermal properties. Standard thicknesses of gap fillers tend to be 0.25-5mm (10-200 mils). They feature deflection without excessive pressure. Gap fillers need to be relatively compliant to achieve high deflections without generating excess pressure within an application.

The optimal properties of gap filler materials include low total thermal resistance, high thermal conductivity, and low contact resistance (good surface wetting). They should be easy to handle. There is a need for low outgassing/low bleeding. Excessive outgassing can cause silicone to condense and build up on optical applications.

For sourcing gap fillers supplier in UK, you may want to explore specialized suppliers catering to electronic components and thermal management materials.

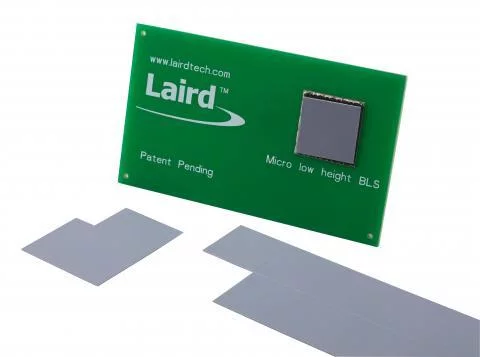

Also check out Laird’s liquid gap fillers.

How do They Work?

Thermal gap fillers are formulated in the lab and placed into electronic devices and systems to get into those small pockets of air, small gaps in space between hot components and a chassis or heat sink assembly. These gaps create thermal barriers to heat transfer due to the low thermal conductivity of air. Gap filler formulations provide the answer using their high thermal conductivity. They bridge what had been an air-filled interface. Gap fillers successfully transfer heat from sensitive components and help keep devices compliant and within prescribed heat limits.

What are Common Uses?

Gap fillers are use widely to help resolve heat mitigation issues in electronic devices. Some of the industries and products utilizing gap fillers are automotive ADAS, automotive lighting, infotainment and powertrain, drones/satellites, gaming systems, instrumentation, notebooks/tablets, portable devices, routers, smart home devices, test and measurement equipment, and wireless infrastructure.

Gap Fillers Series

Silicone based Thermal Gap Filler Laird’s Tflex™ HD7.5 gap filler is a new developed very soft silicone material in our

Thermal Gap Filler Laird Tflex™ HD300TG is a 2.7 W/mK gap filler material in Laird’s high deflection line of products.

Silicone based Thermal Gap Filler Laird Tflex HD300 is a 2.7 W/mK gap filling material in our high deflection line

Silicone based Thermal Gap Filler Tflex B200 is a reliable, compliant thermal interface material offering good thermal performance and easy

Silicone based Thermal Gap Filler Product Description EXCEPTIONALLY SOFT, HIGHLY COMPLIANT GAP FILLER Tflex 600 is an exceptionally soft, highly

Silicone based Thermal Gap Filler Compliant 2.8 W/mK Thermally Conductive Gap Filler Tflex 50000 is a compliant elastomer gap filler

Silicone based Thermal Gap Filler Tflex 300, at pressures of 50psi, will deflect to over 50% the original thickness. This

Ultra-thin Thermal Gap Filler Ultra-thin gap filler offering great thermal performance and handling. Tflex UT20000 is a specially formulated ultra-thin

Silicone Free Thermal Gap Filler Compliant Silicone-Free 3.0 W/mK thermally conductive Gap Filler Tflex SF600 is a high performance silicone-free

Silicone based Thermal Gap Filler Tflex HD90000 combines 7.5 W/mK thermal conductivity with superior pressure versus deflection characteristics. The combination

Silicone based Thermal Gap Filler Tflex 700 is a 5 W/mK soft gap filler thermal interface material with great thermal

Silicone based Thermal Gap Filler The high rate of compliancy of Tflex 300TG allows the material to totally blanket the